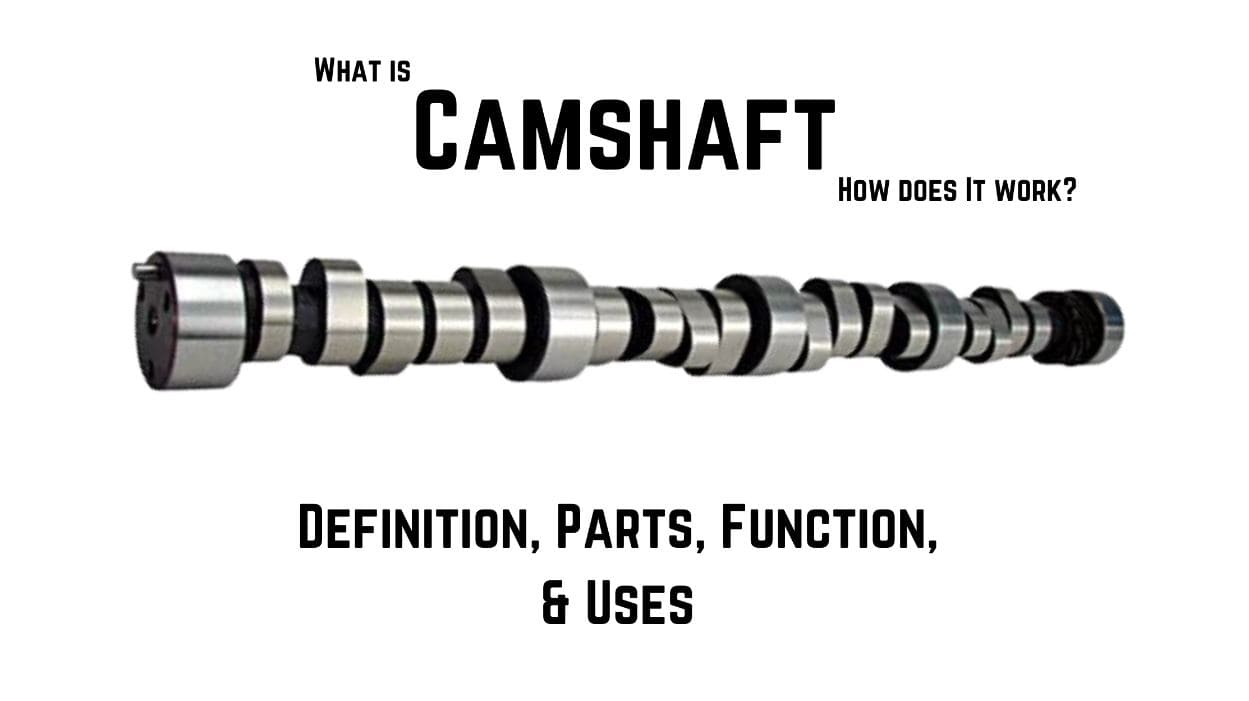

Engine Camshaft

An Engine Camshaft is simply a shaft on which cams are mounted the camshaft is mounted in bearing in the lower part of the cylinder block in most in-line engines. in a few engines, it is located on the cylinder head.

a cam is a device that changes the rotary motion of the camshaft into the linear motion of the follower or lifter. Then Cam has a high spot or lobe . the follower riding on the will move away from or toward the camshaft as the cam rotates

a camshaft is responsible for opening the valve. A camshaft has a number of cams along the length two cams for each cylinder one ato operate the inlet valve and the other to the exhaust valve.

The engine Camshaft has an eccentric to operate the fuel pomp and gear to drive the ignition distributor and oil pump.

the camshaft is driven by the crankshaft either by a pair of meshing gears (timing gears) or by means of a pair of timing sprockets connecting by a chain. the camshaft gear or sprocket has twice as many teeth as the gear or sprocket on the crankshaft. this given 1:2 gear ratio the camshaft turns at half the speed of the crankshaft. thus every two revolutions of the crankshaft produce one revolution of the camshaft and one opening time relationship between the camshaft and crankshaft to ensure opening of the valve exactly at the correct time in relation to piston position. timing marks on the gears and sprocket are used to set the shaft in the correct time with each unit are assembled. in the small circle on the crankshaft timing gear must fall between the two small circles on the crankshaft timing gear to ensure correct valve timing. the marks of the sprockets are in a straight line with the centers of both shafts to ensure correct valve timing.

Parts of Camshaft

Following are the main parts of camshaft assembly:

- Cam bearing journals

- Bearing Shells

- Lobes

- Thrust plate

- Chain sprocket

- Woodruff key

1. Cam Bearing Journals

The cam is a rotating component that provides reciprocating or oscillating motion to the follower by direct contact. This is typically used to change the movement from the rotary to linear.

2. Bearing Shell

The bearing shell is part that is mounted on the cam bearing journals. It helps to protect the camshaft from breaking the engine block in case of engine failure. Bearing shells keep the camshaft in a smooth rotation.

3. Lobes

During the rotation of the camshaft, the lobes work with the motion of the piston. The purpose of lobes is to open and close the valves for intake and exhaust gases. Its speed usually depends on the engine speed.

4. Thrust Plate

When using a roller cam you will need to provide some means to support the cam at the rear of the engine. The thrust plate is attached between the cam and timing gear and mounted on the front cover for proper end play.

5. Chain Sprocket

A chain sprocket is attached to the camshaft end of the engine to retain the timing belt. This sprocket is attached to a chain. These sprockets are capable of turning at the same speed even if they do not touch.

6. Woodruff Key

The woodruff key is also the main part of the camshaft of the engine that is used to retain the cams at the right time.

How does engine camshaft work?

The camshaft is operated by the crankshaft either by a pair of meshing gears (timing gears) or a pair of timing sprockets connected by chains. The camshaft gear or sprocket has as many teeth as the gear or sprocket on the crankshaft.

This gives a 1:2 gear ratio. The camshaft rotates at half the speed of the crankshaft. Therefore every two revolutions of the crankshaft create one revolution of the camshaft and one opening and closing of each valve in the four-cylinder engine.

The gear and sprocket maintain a definite time relationship between the camshaft and crankshaft to insure opening the valves exactly at the correct time in relation to piston position.

Timing marks on the gears and sprockets are used to set the shaft incorrect times with each other when the units are assembled.

The figure shows that the smaller circle on the crankshaft timing gear must fall between the two smaller circles on the crankshaft timing gear to ensure correct valve timing. The sprocket marks are in a straight line with the centers of both shafts to ensure correct valve timing.

Material used for Camshaft

An engine camshaft is made of solid metal to achieve greater rigidity. Camshafts are usually made of cast iron as it gives more strength and is also used for mass production.

A chilled iron camshaft can give you good wear resistance and hence the chilling process hardens the material. A variety of materials are mixed with iron to form more suitable properties for the purpose of its application.

Some manufacturers also use billet metal when high quality and low production is required. However, it requires more time and cost than other methods. It is manufactured by forging, casting, or machining on a lathe and milling machine.

Causes of a Failure Camshaft

Many problems can be created on the camshaft. If you neglect these problems, it can cause you a heavy loss and complete breakdown of the engine.

The following are the causes of the damaged camshaft:

- Due to the wear of the lobe.

- Due to the improper brake-in.

- Because of the damaged cam of a camshaft.

- Using oil filters with a new cam.

- Due to mechanical interference occurrences such as spring coil bind, retainer to seal, valve to piston interference, and rocker arm slot to stud.

- Because of the large end play provided on the camshaft.

- Due to the usage of cheap dowel pins or Woodruff keys.

- Because of the incorrect pressure of the valve spring.

How does an engine camshaft work?

The camshaft is a crucial component in an internal combustion engine, responsible for controlling the opening and closing of the engine’s intake and exhaust valves. It plays a key role in determining the engine’s performance by regulating the timing and duration of these valve events.

Here’s a basic explanation of how a camshaft works:

- Location and Design: The camshaft is usually located in the engine block or cylinder head, and it has a series of lobes or cams along its length. These lobes are specifically shaped to control the valve movements.

- Connection to Crankshaft: The camshaft is connected to the crankshaft, which is responsible for converting the linear motion of the pistons into rotational motion. This connection is often made via a timing belt or chain.

- Cam Profile: Each lobe on the camshaft has a unique shape, known as the cam profile. The cam profile determines the timing and lift of the valve it controls. The shape of the cam lobe is designed based on the engine’s performance requirements.

- Valve Actuation: As the camshaft rotates, the lobes push against lifters (or tappets), which in turn push against pushrods or directly act on the valves. This action causes the valves to open and close at specific points in the engine’s four-stroke cycle.

- Timing and Duration: The position and shape of the cam lobes determine the timing and duration of valve events. The timing refers to when the valve opens and closes in relation to the position of the piston in the cylinder, while duration refers to how long the valve stays open.

- Overlap: Overlap is a critical concept in camshaft design. It refers to the period when both the intake and exhaust valves are partially open at the same time. Proper overlap can enhance engine efficiency and performance.

- Adjustability: In some engines, the camshaft’s position can be adjustable, allowing for changes in valve timing and duration. This adjustability can optimize engine performance under different conditions.

In summary, the camshaft converts the rotational motion of the crankshaft into precise valve movements, ensuring that the intake and exhaust valves open and close at the right time. This precise control is essential for optimizing engine efficiency, power, and emissions.

1. What is a Camshaft?

At its core, a camshaft is a shaft with protruding cams, which are lobes or projections that operate the valves in an engine. It’s essentially the conductor of the orchestra that is your engine, dictating the precise timing and duration of the opening and closing of the valves.

2. Types of Camshafts

There are various types of camshafts, including overhead camshafts, which are situated above the cylinder head, and inline camshafts, which are located within the engine block. Each type has its advantages and is tailored to different engine designs.

3. How Camshafts Work

Imagine the camshaft as a series of bumps on a rotating rod. As the camshaft spins, these bumps push against valve lifters, causing the valves to open and close at specific intervals. This process synchronizes with the engine’s pistons, allowing for precise control over the combustion cycle.

4. Role of Camshafts in Engine Performance

The performance of your engine heavily relies on the camshaft’s ability to regulate airflow and fuel intake. By optimizing valve timing and lift, camshafts can enhance power output, fuel efficiency, and overall engine responsiveness.

5. Camshaft Belt vs. Timing Chain

One common debate in the automotive world is whether to use a camshaft belt or a timing chain. While both serve the same purpose of synchronizing the camshaft with the crankshaft, they differ in terms of longevity and maintenance requirements.

6. Understanding Camshaft Profiles

Camshaft profiles refer to the shape and size of the cams, which directly impact valve lift and duration. Profiles can vary significantly, from mild street cams designed for daily driving to aggressive racing cams optimized for high-performance applications.

7. Choosing the Right Camshaft

Selecting the appropriate camshaft for your engine involves considering factors such as intended use, engine displacement, and desired power band. Consulting with experts or utilizing camshaft selection tools can help you make an informed decision.

8. Installation and Maintenance

Proper installation and regular maintenance are crucial for maximizing the lifespan and performance of your camshaft. This includes ensuring precise timing alignment, adequate lubrication, and periodic inspections for wear and tear.

9. Upgrading Your Camshaft

For enthusiasts seeking to extract more power from their engines, upgrading the camshaft is a popular modification. However, it’s essential to carefully match the camshaft specs with other engine components to avoid compatibility issues and achieve optimal results.

10. Frequently Asked Questions (FAQs)

Q1. What are the signs of a failing camshaft?

Signs of a failing camshaft include rough idling, decreased engine performance, and unusual engine noises.

Q2. Can I install a camshaft myself?

While it’s possible to install a camshaft yourself, it’s recommended to seek professional assistance to ensure proper installation and timing.

Q3. How often should I replace my camshaft belt?

Camshaft belts should typically be replaced every 60,000 to 100,000 miles, depending on the manufacturer’s recommendations.

Q4. What is the difference between a camshaft and a crankshaft?

While both camshafts and crankshafts play essential roles in engine operation, camshafts control valve timing, while crankshafts convert linear motion into rotational motion.

Q5. Are aftermarket camshafts worth it?

Aftermarket camshafts can significantly improve engine performance but require careful consideration of compatibility and tuning to achieve optimal results.

By understanding the intricate workings of engine camshafts, you’ll gain a newfound appreciation for the marvels of automotive engineering. Whether you’re maintaining your daily driver or fine-tuning a high-performance machine, the camshaft remains a fundamental aspect of engine design and performance.

What are the three functions of the camshaft? | What is the function of the camshaft?

The camshaft serves three fundamental functions in an internal combustion engine. Firstly, it regulates the timing of the engine’s intake and exhaust valve openings and closings. This timing is crucial for synchronizing the valve events with the engine’s piston movements, ensuring efficient combustion and optimal power delivery. Secondly, the camshaft controls the duration of valve opening, influencing the amount of air and fuel entering the combustion chamber and the exhaust gases leaving it. This aspect directly impacts engine performance, fuel efficiency, and emissions. Lastly, the camshaft governs valve lift, determining how far the valves open during each cycle. Valve lift affects the engine’s ability to draw in air and expel exhaust gases, influencing overall power output. In essence, the camshaft’s triple role in timing, duration, and lift is paramount to achieving a balance between performance, efficiency, and emissions in internal combustion engines.

What is the difference between a camshaft and a crankshaft?

Following are the main points of difference between camshaft and crankshaft:

| Camshaft | Crankshaft |

|---|---|

| As the engines work they need to breathe out exhaust gases and take in fresh air for the next cycle to take place. | This part of an engine is a shaft as the name suggests on which all the units of an engine are mounted. |

| A camshaft is generally made of cast iron or steel by casting process or machining on lathe or milling machine. | A crankshaft is typically made of alloy steel by the forging process. |

| The camshaft is located at the top of the cylinder head. | The crankshaft is located at the bottom of the cylinder head. |

| A camshaft is used to open or close the engine valve for the right timing. | A crankshaft is employed to convert the reciprocating or oscillating motion of the piston into rotary motion. |

| The camshaft is rotated by the timing belt and is attached to the crankshaft. | The crankshaft is rotated with the help of a piston. |