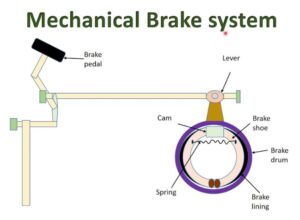

Mechanical Brake :- Mechanical Brake is Used for Light Vehicle. the wheel is attached to an auxiliary wheel called Drum. the brake shoes are made to contact this drum. mainly in bike Moter Cycle Scooter In this type of brake system power in transmitted through mechanical linkage From Brake paddle to the brake Shoes to Actuate on brake Drum on Wheel rim

Main Function Of Brake System

- Control the driving of the Vehicle

- IT Stop the Vehicle and slow Down the Speed of the vehicle

- It must have strong braking farce

- It Must operate easily

The wheel attached to an auxiliary wheel called Drum. the Brake Shoes are made to contact this Drum in most designs two shoes are used with each drum to form a complete brake mechanism at each wheel , the Brake Shoes have brake linings on their outer Surface. Each brake shoe is hinged at one end by an anchor pin, the other end is operated by some means so that the brake shoe expand

Mechanic Brakes parts:-

- Brake Drum

- Brake Shoe

- Brake Lining

- Toggle Lever

- Retractor spring

- Anchor Pins

A drum brake is a brake in which the friction is caused by a set of shoes or pads that press against a rotating drum-shaped part called a brake drum.

Brake Lining :- This material was designed for low temperatures and high friction. The material offers excellent riveting strength and is suitable for gluing. It offers limited oil resistance and is not recommended for applications immersed in oil.

Retractor spring:-The job of the retractor spring is to keep the shoe away from the brake drum. When the shoe turns forward through the cam, the retractor springs back to you. It is used to retract the brake shoe after brake is applied. Two return springs are there in durm brake, one for the primary shoe and other one is for secondary shoe.

Anchor Pins:- The job of Anchor Pins is to keep the Brake Shoe fixed in one place. It maintain the minimum gap between the brake shoe and drum so that they do not contact each other when pedal is not pressed. In the case if the brake lining wear out, and gap increases in between the shoe and drum, It can be adjusted again to maintain the gap between shoe and drum inner surface. once it is adjusted it maintains the same gab during the brake working by itself.

Advantages

- They are self energizing braking system. It means they are designed to operate by itself.

- It is cheaper than the disc braking system.

Disadvantages

1. Heating problem: Since the friction area is totally covered by lining, so heat is developed during the friction is not allowed to go out in the atmosphere. This may reduces the braking efficiency of the vehicle.

2. The drum brakes will not work properly if it gets wet in water. This is because water takes longer time to come out from the drum. the water reduces the friction in between the brake lining and drum.

In this article we have learnt about how drum brakes works and its main parts, working principle with advantages and disadvantages . If you like this article than don’t forget to share