This blog post provides knowledge about crankshaft, crankshaft material, crankshaft function. This blog is about the crankshaft, types of the crankshaft, functions of the crankshaft. This blog post provides knowledge about crankshaft, crankshaft material, crankshaft function, types of crankshaft.

Crankshaft

The crankshaft converts the reciprocating motion of the piston into rotational motion. With the help of connecting rod . A crank pin webs balancing weights and main journals big end of the connecting rod is connected to the crankpin of the crankshaft. center to center distance Between The crankpin.

The Crankshaft is made of casting or forging of heat treated alloy steel and is machined and ground to provide suitable journals for the connecting rod and main bearings

Functions of crankshaft.

- It transmits the power from the engine cylinder to the flywheel and gearbox.

- The crankshaft helps to maintain the firing order of the engine.

- The crankshaft balances engine dynamics, vibrations, centrifugal forces.

- It provides drive to the camshaft, engine fuel pump, water pump, oil pump, engine alternator, steering pump, and A/C compressor.

How does crankshaft work?

Please watch the below GIF to understand how does crankshaft works.

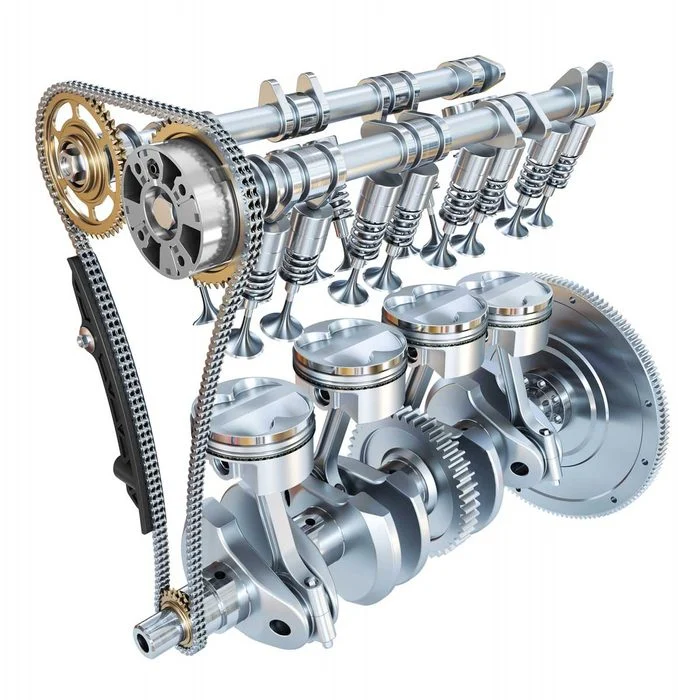

The above animation helps to understand how the reciprocating motion of the piston is converted into a rotational motion. In a multi-cylinder engine, the crankshaft must maintain engine dynamics without affecting the firing order of each cylinder. The power generated by the crankshaft is further transmitted to the camshaft by toothed belt drive (known as timing belt) of by chain (known as timing chain). Timing chains are mostly used for a single-cylinder engine where space is constrained.

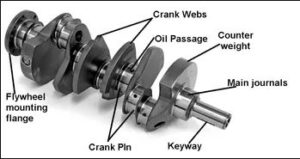

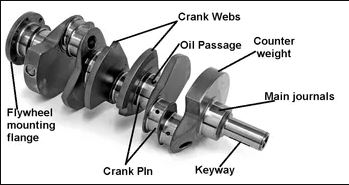

Construction of Crankshaft

- Main bearing journals

- Crankpin

- Flywheel end

- Crank web & Balancing weight

- Oil hole and oil passage

- Pulley end

The functions of each section of the crankshaft parts.

- Main bearing journals: the parts of the crankshaft inside the main bearing journal. The crankshaft is supported by the main Bearings on the main journals.

- Crankpin: The function of crankpin is to provide a pivot point for connecting rod. The distance between the crankpin radius and crankshaft is known as the crank radius.

- Crankshaft Front End: The front end of the crankshaft carries three devices the gear or sprocket that drivers the camshaft , the Vibration damper to control Torsional Vibration, and the fan belt Pulley. This Pulley Drives The engine fan, water pump and generator with a V-Belt.

- Crankshaft Rear End: the rear end of the crankshaft carries flywheel. the inertia of the flywheel tend to keep the crankshaft turning at constant speed.

- Flywheel end: At this section of the crankshaft flywheel mounted.

- Balancing weight: Counterweights provide a balancing effect on the piston and connecting rod. As the crankshaft rotates at a higher speed, it’s very necessary to balance centrifugal force. Balancing works as a pivot point, it forms an axis of rotation. The crankshaft main journal bearing surface must be free from irregularities as it is subjected to rotational and centrifugal forces. For in-line cylinder engine number of main bearing journal = Number of cylinder + 1.

Types of Crankshaft:

Depending on the number of cylinders crankshaft types decided.

the Crankshaft Should Be Inspected For:-

- Soundness to check cracks.

- Roundness and wear of journals and Crankpins

- Balancing.

- Alignment of crankpins and Journals.

- Cleanliness of oil galleries.

Design parameters of Crankshaft:

- The crankshaft should withstand high centrifugal forces generated due to the reciprocating movement of piston and cylinder at high speed.

- The crankshaft must withstand high working temperatures.

- The crankshaft must withstand torsional load/stress during the power stroke of each cylinder.

- The smooth surface finish on the crankpin and main journal bearing must be maintained to avoid wear and tear of an engine bearing.

- The crankshaft must sustain the axial load generated due to the clutch spring load.

- The crankshaft must have good fatigue strength.

- Geometric tolerances and dimensions on the crankshaft must be maintained in a proper way for smooth functions of engine components like a piston, connecting rod, camshaft, valves, etc. Refer following animation, how the crankshaft drives other engine components.

Crankshaft material | How crankshafts are manufactured?

Casting is the most common manufacturing method used for the crankshaft. The forging method is also used for crankshaft manufacturing. After forging machining operation is necessary to maintain a smooth surface finish on the crankpin and main journal bearing surface.

Quality Assurance and Quality Control in Crankshaft

Smooth functions of the crankshaft are very essential for better engine efficiency. Engine with defective crankshaft turns in to the poor performance of the engine. Following Quality assurance and Quality control methods mostly used in industry,

[…] Crankcase […]

[…] Crankcase […]

[…] and heat energy mechanical energy में convert होतीं है जिससें Crank Shaft rotate करती है. Internal combustion engine में fuel के रूप में […]

[…] Crankcase […]

[…] and heat energy mechanical energy में convert होतीं है जिससें Crank Shaft rotate करती है. Internal combustion engine में fuel के रूप में […]

[…] Crankcase […]

[…] Crankcase […]

[…] Crankcase […]

[…] Crankcase […]