Hydraulic Brake SYSTEM:- the hydraulic brakes are applied by the liquid pressure. the pedal Force is transmitted to the brake shoe by means of a confined liquid through a system of force transmission the Force applied to the pedal is multiplied and transmitted to all the brake shoes by a force transmission system. this system is based upon pascal’s low which state that the confined liquid transmit pressure without loss equally in all direction. In most of the Vehicle Hydraulic Brake System is used Hydraulic Brake System Work on Pascal’s Low

PASCAL LOW According to this Low it non-Viscous in Compressible Liquid is kept in a closed vassal and some pressure is applied in it any one side it would be equally transmitted in all direction it out diminishing

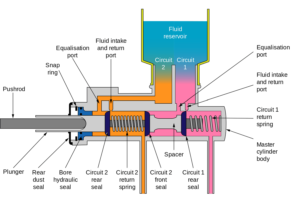

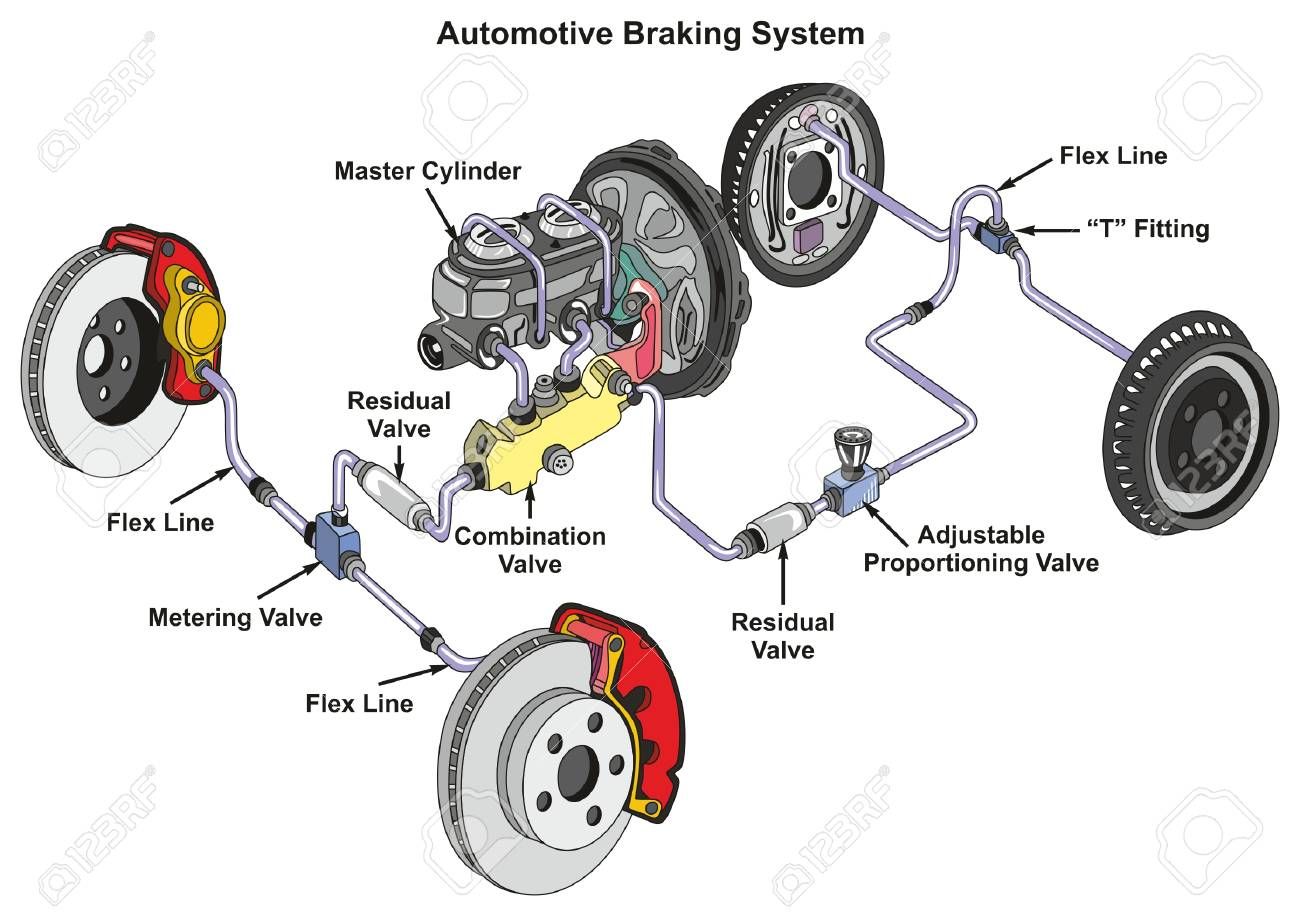

Hydraulic Brake System it essentially consist of two main components master cylinder and wheel cylinder.

Parts Of the Hydraulic Brake System

Following are Parts of the brake system:

- Brake Pedal

- Master Cylinder

- Brake Pads

- ABS Control Module

- Brake Booster

- Disc Brakes

- Drum Brakes

- Emergency Brake

- Brake Pedal

- Wheel Speed Sensors

Brake Pedal

The pedal is what you push with your foot to activate the brakes. It causes brake fluid to flow through the system to put pressure on the brake pads.

Driver steps on the brake pedal to activate the brakes. A piston in the master cylinder moves when the pedal is pressed.

2. Master Cylinder

The master cylinder is basically a plunger that is activated by the brake pedal. It is what holds the brake fluid and forces it through the brake lines when activated.

Converts non-hydraulic pressure into hydraulic pressure that the wheel cylinders use to press the brake pads against the rotors to bring the vehicle to a stop.

3. Brake Lines

Generally made of steel, brake lines are what carry the brake fluid from the master cylinder reservoir to the wheels where pressure is applied to stop the car.

4. Wheel Cylinders

The brake pads are connected to the wheel cylinders which either squeeze (disc brakes) or push apart (drum brakes) the brake pads when fluid flows into them.

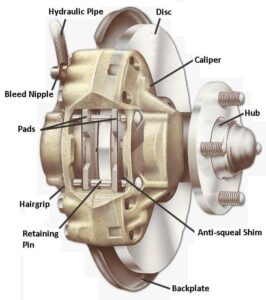

5. Brake Pads

The brake pads are what actually rub against the drums or rotors. They are made of composite materials and designed to last for many, many thousands of miles. However, if you ever hear a grinding or howling noise when you try to stop your car it likely means it is time for new brake pads.

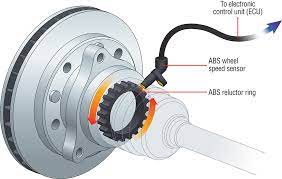

6. ABS Control Module

Found on vehicles with ABS brakes, the module performs diagnostic checks of the ABS braking system and determines when to send the correct pressure to each wheel to prevent the wheels from locking up.

7. Brake Booster

Reduces the amount of pressure needed for braking to allow any driver to operate the brakes. Uses engine vacuum and pressure to increase the force the brake pedal puts on the master cylinder.

8. Disc Brakes

Usually found on the front wheels, disc brakes feature brake pads that press against a disc (rotor) when the brake pedal is applied to stop the vehicle. The pads are attached to a brake caliper assembly that frames the rotor.

9. Drum Brakes

Located on the rear of the vehicle, drum brakes feature wheel cylinders, brake shoes and a brake drum. When the brake pedal is pressed, the brake shoes are forced into the brake drum by the wheel cylinders, bringing the vehicle to a stop.

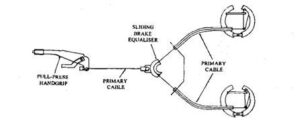

10. Emergency Brake

Operates independently of the main brake system to keep the vehicle from rolling away. Also known as a parking brake, hand brake, and e-brake, the emergency brake is mainly used to keep the vehicle in place when parked.

11. Wheel Speed Sensors

Part of the ABS brake system, speed sensors monitor the speed of each tire and sends the info to the ABS control module.

BRAKE OIL SPECIFIC CHARACTERISTICS

- Brake oil should be non viscous (Low -Viscosity)

- It Should be in Compressible

- It’s Boiling Point should be High It’s Freezing Point Should be Low

- It Does Not React with the material of pipe Through Which it pases

- It’s specific heat should be High

Brake Shoes Re made of Special Type Of material

- Iron nail and Particles

- Asbestos Dust

- Binding material

- Hardening Material

They are mixed Together and given Desived a shape and size . after solidifying they are used as brake Shoes.

Classifications of brakes

With Respect to application

- (a) Foot Brake

- (b) Hand Brake

With Respect to the Number of wheels:

- (a) Two- Wheel Brake

- (b) Four Wheel Brakes.

With Respect to the Brake Gear

- (a) Mechanical Brakes

- (b) Power Brakes

With Respect to the nature of power

- (a) Vacuum Brakes

- (b) Air Brakes

- (c) Hydraulic Brakes

- (d) Electric Brakes

With Respect to power unit

- (a) Direct Acting Brakes

- (b) Diaphragm brakes.

[…] Hydraulic Brake System […]

[…] Hydraulic Brake System […]

[…] Hydraulic Brake System […]