Now we will understand “Single Plate Clutch” and its working –

What Is A Single Plate Clutch?

Single plate clutch :– It is the Most Common types of clutch used in motor Vehicles it consists of only clutch plate the the flywheel is mounted on the engine crank shaft and rotates with it the pressure plate is bolted to the flywheel through clutch spring when the clutch is engaged the clutch plate is gripped between the flywheel and the pressure plate when the clutch pedal is pressed the pressure plate move bake against the force of the spring and the clutch plate become free between the flywheel and the pressure plate.

Working Of Single Plate Clutch

When the engine is running and therefore the flywheel is rotating, the pressure plate also rotates because the pressure plate attaches to the flywheel. The friction disc is located between the flywheel and the pressure plate. When the driving force has pushed down the clutch is released. The pressure plate is bolted to the flywheel through clutch springs and is free to slide (Move) on the clutch shaft when the clutch pedal is operated (Engage and Disengage).

- The working of single plate clutch is quite simple to understand. In this we can easily engage and disengage the torque transmission shafts of the automobile by applying some force to the paddle.

- There is a Lever which is attached to the Paddle and it transmits the Force from the Paddle. And when we press the paddle, the spring gets compressed, at this time the engine which is able to move easily without any load.

- The lever is connected in such a way that when we depress the clutch paddle the thrust bearing moves forward and the pressure plate moves backward and it moves away from the flywheel. In this, the connection between the clutch plate and the flywheel breaks down and the shaft disengages, at this time we can easily change the gears in the automobile.

- Now if we want to connect the shaft again, then we just leave the paddle that is. After this, the springs that remain attached to the pressure plate push the pressure plate forward, so that the shafts are reconnected.

- The clutch plate is mounted on the hub between the pressure plate and the flywheel. Friction lining is maintained on both the sides of the clutch plate and it helps in torque transmission. This was the working of single clutch plate if you want to know it in detail then write in comment

Clutch Engaged

- When the clutch is engaged (which Means when you not pressed the clutch pedal), the clutch plate is held between the flywheel and the pressure plate.

- The friction linings are on both sides of the clutch plate. The clutch disc rotates the flywheel due to the friction between the flywheel, the clutch disc, and the pressure plate.

- The clutch shaft also rotates with the clutch plate. The clutch shaft is connected to the gearbox. Now the engine power is transferred to the crankshaft and then to the clutch shaft and gearbox.

- Clutch always engaged because of the spring forces.

If Clutch Disengaged

- When the clutch is disengaged (which Means when you pressed the clutch pedal), the pressure plate moves back against the force of the springs, and the clutch plate is released between the flywheel and the pressure plate.

- The flywheel always rotates with the crankshaft. Then the speed of the clutch shaft will slowly decrease and stop rotating.

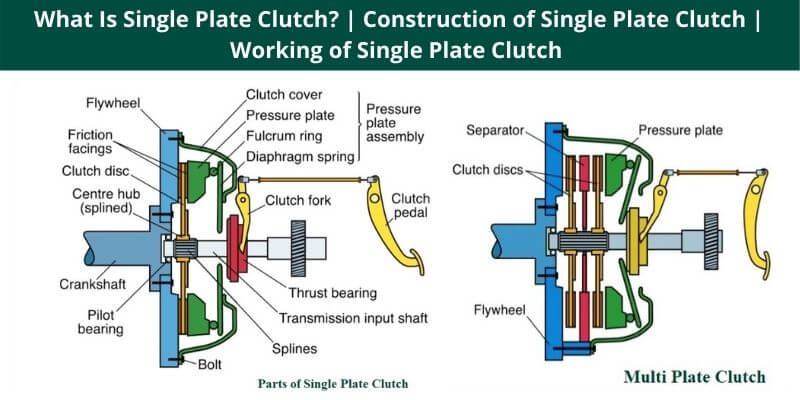

Single Plate Clutch Diagram

Parts Of Single Plate Clutch

A single plate clutch assembly for transmission of power consists of a flywheel, a clutch plate, pressure plates, clutch covers, release levers, primary or clutch shaft.

- Flywheel

- Pilot Bearing

- Clutch plate or Disc plate

- Pressure plate

- Clutch cover

- Release levers

- Clutch shaft

1) Flywheel

- The flywheel is an integral part of the engine, which also use as a part of the clutch. It is a driving member and connects to the pressure plate of the clutch shaft is houses with bearings in a flywheel. The flywheel rotates as the engine crankshaft rotates.

2) Pilot Bearing

- The pilot bearing or bushing press into the end of the crankshaft to support the end of the transmission input shaft. The pilot bearing prevents the transmission shaft and clutch disc from wobbling up and down when the clutch releases. It also assists the input shaft center of the disc on the flywheel.

3) Clutch Plate Or Disc Plate

- It is the driven member of the single-plate clutches and line with friction material on both surfaces. It has a central hub with internal splines to limit the axial travel along the splined gearbox driving shaft.

- This helps to provide damping actions against torsional vibrations or variations of the driving torque between engine and transmission.

- A clutch disc is a plate between flywheel and friction or pressure plate. It has a series of facings inverters on each side to enlarge the friction. These clutch facings are made of asbestos material. They are highly worn and heat resistant.

4) Pressure Plate

- The pressure plate is made of special cast iron. It is the heaviest part of the clutch assembly. The main function of the pressure plate is to establish even contact with the driven plate facing through which the pressure springs can exert a sufficient force to transmit the full torque of the engine.

- The pressure plate presses the clutch plate on to the flywheel from its machined surface. Between the pressure plate and clutch cover assembly, pressure springs are fitted.

- The pressure will be withdrawn from the flywheel whenever release levers are depressed by the toggle or release levers are pivoted accordingly.

5) Clutch Cover

- The clutch cover assembly bolts to the flywheel. It consists of a pressure plate, release lever mechanism, clutch cover, and pressure springs. Generally, the clutch plate revolves with the flywheel.

- However, when the clutch has disengaged, the flywheel, as well as the pressure plates, are free to rotate independently from the driven plate and driving shaft.

6) Release Levers

- These pivots on pins to the clutch cover, their outer ends locate and positions on pressure plate legs, and the inner ends are projecting towards the clutch shaft.

- A careful and accurate adjustment of the release mechanism is one of the most important factors governing the performance of a clutch assembly.

7) Clutch Shaft

- It is a component of the gearbox. Since it is a splined shaft to the hub of the clutch plate, which is sliding on it. One end of the clutch shaft attaches to the crankshaft or flywheel and the other end connects to the gearbox or forms a part of the gearbox

Types Of Single Plate Clutch

- Helical Spring Single Plate Clutches

- Diaphragm Spring Single Plate Clutches

1. Helical Spring Single Plate Clutch

For simplicity’s sake, the clutch pedal and other links causing movement of the pressure plate are not shown.

The clutch plate is mounted on the splined shaft and can move along the axis of the shaft. There is no relative movement between plate and shaft as far as rotational movement is concerned.

Both have the same rotational movement due to splines provided on the shaft. The flywheel is mounted on the engine crankshaft and rotates with it. The pressure plate is bolted to the flywheel through clutch springs. It can slide freely along the axis of the clutch shaft.

The clutch is engaged due to the force exerted by the clutch springs. This force causes contact between the pressure plate, clutch plate, and flywheel. The clutch plate is located between the flywheel and the pressure plate. The clutch plate is provided with friction material on both sides.

The rotary movement from the flywheel is transferred to the clutch plate and the clutch shaft due to friction. The clutch shaft also acts as the output shaft.

When the clutch pedal is pressed the clutch is ‘disengaged.’ The pressure plate moves back against the force of springs, and the clutch plate becomes free between the flywheel and the pressure plate.

Thus, the flywheel continues to rotate as long as the engine runs but the speed of the clutch plate declines and becomes zero. In this situation, motion is not transferred to the clutch shaft.

2. Diaphragm Spring Single Plate Clutch

In this type of clutch, the helical springs are replaced by a single diaphragm spring which is a saucer-shaped disc. The disc adopts a flat shape when the clutch is engaged. In the disengaged position, the disc adopts a buckled shape as shown.

The view shows the clutch in the ‘engaged’ position. The diaphragm spring exerts the force on the pressure plate, which causes the contact between the pressure plate, clutch plate, and flywheel.

When force is applied through the clutch pedal, the diaphragm spring is buckled and contact between the pressure plate, clutch plate, and the flywheel is lost. The clutch is disengaged,’ and motion from the flywheel is not transferred to the clutch shaft.

Application Of Single Plate Clutch

Single plate clutch applications are as follows :

- Single plate clutches are used in Buses, Trucks, and cars, etc.

- Single plate clutches are used where large radial space is available.

- This type of clutch does not require any lubricant for cooling.

- As sufficient surface area is available for the heat dissipation in Single plate clutches, no cooling oil is required. Therefore, single plate clutches are dry type.

- Due to the high coefficient of friction, most of the vehicles use a single plate clutch. The amount of the coefficient of friction is more than 0.3.

Advantages Of Single Plate Clutch

The main advantages of this clutch include:

- Single plate clutch is smooth in operation i.e engagement and disengagement of clutch is smooth.

- Very little slip occurs in its operation. Slip only occurs during the engagement of the clutch and after that, no slipping occurs and functioning becomes very smooth.

- Power loss is very less.

- Very little heat is generated as only one clutch plate is used.

- The operation in this type of clutch is very fast.

Disadvantages Of Single Plate Clutch

The main disadvantages of this clutch include:

- Single plate clutches have high wear and tear rate.

- It has less torque transmitting capacity.

- The springs have to be stiffer hence greater force requires to disengage.

- It requires high maintenance.

- The space required to accommodate the clutch is more as compared to the multi-plate clutch.

Clutch Material

There are so many materials that have been used for making the clutch plates.

Semi-Metallic Materials: This type of material contains 30% to 65% of steel, iron, and copper. These clutches have high heat resistance and are hard to break and those are durable enough. The plates are reliable but not that good for high-speed operation.

Organic Materials: These are the most common type of materials that we used the most. These materials clutches are capable of all kinds of usage in a variety of vehicles such as size. This material contains high copper content because that it can transfer heat effectively.

Ceramic Materials: These types of clutches contain organic and inorganic materials at the same time which include glass, rubber, Kevlar, and carbon materials. In this clutch, the coefficient of the friction is relatively high which lies between 0.33 to 0.4. In most the intense applications, this type of clutch is used, like in trucks and racing cars.

FAQs.

What is Single plate Clutch?

Single plate clutch is the most common type of clutch plate used in automobiles. It consists of only one clutch plate which is mounted on the splines of the clutch plate. The Flywheel is mounted on the engine crankshaft and rotates with it.

What are the parts of a single plate clutch?

Parts of Single Plate Clutch:

1. Flywheel

2. Pilot Bearing

3. Clutch plate or Disc plate

4. Pressure plate

5. Clutch cover

6. Release levers

7. Clutch shaft

What are the types of Single plate clutch?

A single plate clutch has one clutch plate and works on the principle of friction. These are of two types: the Helical spring type and the Diaphragm spring type. In helical spring-type clutches, the helical springs are used uniformly over the cross-sectional area of the pressure plate to exert axial force.