What is gear and its function?

- A gear drive has three main functions: to increase torque from the driving equipment (motor) to the driven equipment, to reduce the speed generated by the motor, and/or to change the direction of the rotating shafts. The connection of this equipment to the gear box can be accomplished by the use of couplings, belts, chains, or through hollow shaft connections.

- Speed and torque are inversely and proportionately related when power is held constant. Therefore, as speed decreases, torque increases at the same ratio.

Gears are such circular discs on whose circumference the teeth are cut.

- Gear device is used for power transmission or motion transmission between two shafts. Shafts can also be intersecting or can also be non-intersecting. There is no slipping during power transmission in the gear device, so the gear is also called positive drive and gear drives are also called in between the body of two gears.

- By using gears, we do power and motion transmission from direct contact to the gear body. We do not have to use any link and connector in Gears for power and motion transmission in between.

- In order not to have a slipping condition between the gears, it is necessary to have at least one intersection between the gears, only then there will be no slipping between the gears.

- We get a high level of work accuracy from gears, because the ratio (ratio) of the angular velocities of two gears is constant.

Gears do not have kinetic friction, so there is no loss of energy during power transmission in the gears.

Types Of Gear

- Super Gear

- Worm Gear

- Rack And Pinion

- Bevel Gear

- Helical Gear

Spur Gear

- Spur gears transmit power through parallel shafts. The teeth of the spur gear are parallel to the shaft axis. This causes the gear to generate a radial reaction load on the shaft, but not an axial load. Spur gears make more noise than helical gears because they operate along a single line of contact between the teeth. While the teeth are moving through the mesh, they roll off from contact with one tooth and accelerate on contact with the next tooth. It differs from helical gears in that more than one tooth is in contact and transmits torque more smoothly.

- The spur gear is those whose cut teeth and axis (the axis of the shaft on which the gear is mounted) are parallel. Axes are Straight and Parallel After Axes of Rotation then we call such Gear as Spur Gear. Spur gear is used less in power transmission.

- Spur Gear is used for very low power transmission and only at very low speed. Uses of Spur Gear – Spur Gear is used in sugarcane juice machine.

Helical Gear

- Helical gears have teeth that are oriented at an angle to the shaft, unlike spur gears which are parallel. During this operation more than one tooth comes into contact and helical gears are able to bear more load than spur gears. Because of the load sharing between the teeth, this arrangement allows the helical gear to operate more smoothly and quietly than the spur gear. Helical gears generate a thrust load during operation which needs to be considered when they are used. Most enclosed gear drives use helical gears. Helical gears are gears whose teeth and axis are not parallel. These gears are used to transmit power at an angle, their teeth are cut along the edge angle, so these gears engage more well.

- This is a good way to transmit more torque and power even at high speeds than spur gears and can run without noise. Double

- Helical Gears are also similar, only they have sloping teeth on both sides.

- Such Gear whose Teeth Axis is Straight and inclined towards Axis of Rotation, we call such Gear as Helical Gears.

There are two types of Helical Gears.

- Right hand Helical Gears

- Left hand Helical Gears

- Helical Gears are the most widely used gears.

Uses – Helical Gears are used in automobile gear boxes, machine tool gear boxes, industrial gear boxes etc.

Helical gears are also used in high speed applications such as steam and gas turbines.

The efficiency of helical gears is very high.

To reduce the axial thrust, we use double helical gears, they are also called Herringbone gears. - Uses – Double Helical gears and Herringbone gear are used in heavy machinery like Cranes, Fluid pumps, Military ships etc.

Worm Gear

- Worm gears transmit power through right angles on non-intersecting shafts. Worm gears produce thrust load and are good for high shock load applications but offer very low efficiency in comparison to the other gears. Due to this low efficiency, they are often used in lower horsepower applications.

- Worm & Worm Gear It has a screw called worm and the driven element is some other gear like spur gear, helical it is good to transmit power for slow speed their gear ratio is low in you image The worm gear can be seen when the worm in the motor will rotate, then the spur gear on the driven shaft will rotate, so the gear ratio will be very low.

- Worm and Worm wheel is a very good design to reduce speed.

Spirals are made in Worm and their Spiral angle is very high. The diameter of the worm is very less. We mostly make Worm a driver.

Spirals are also made in worm wheel and their spiral angle is very less. The diameter of the worm wheel is bigger.

Worm and worm wheel are very popular gear to reduce excessive speed and reduce the speed reduction ratio.

Rack And Pinion

They are used to convert rotational motion into linear motion, which is circular gear, it is called pinion. Rack-pinion is also used in steering.

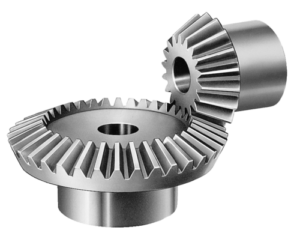

Bevel Gear

- Bevel Gear is used to transmit power at 90°, the best example of this is hand drill machine in which transmits the power of electric motor at 90°, such gears whose both axes are intersecting then we get pure rolling motion. And then pure rolling motion is driven between the two conical surfaces when they are in contact.

- An example of such gears are Bevel gears.

There are three types of bevel gears. - Straight Bevel gear , Zero Bevel gear and , Helical Bevel gear.

Straight and Zero Bevel gears are almost identical. - Usage – Bevel gears are used in hand drill, car differential, shaft-driven bicycle etc.

Spiral gears

- When the axes are neither parallel nor intersecting, we do not get pure rolling motion between two rotating gears.

Examples of such gears are Spiral gears and Skew Bevel gears. - Spiral gears are mostly used for high volume applications. Spiral gears are also used for high speed reduction. Spiral gears are mostly used in Automotive drive systems such as differential gears.

Skew Bevel gears are rarely used because their manufacturing process is very complex. Spiral gears are also used in grass cutting machines, juicers and guitar strings.

Types of Gearing

Gears are also explained on its type of gearing.

It has two types of gears like –

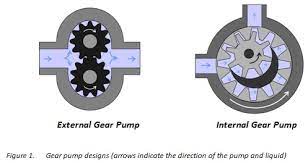

External Gearing.

First we will understand External Gearing in gears as it goes by its name, then it can be said that the teeth on the two gears in External Gearing are made on the outside surface, so we call them external gear and both the gears are one – rotate in the opposite direction to the other. Generally we call the big wheel as Gear and the small wheel is called Pinion.

Internal Gearing

Second, we will understand Internal Gearing in gears, as it also goes by its name, then it can be said that the two gears in internal gearing have teeth on the inner surface, so we call them internal gear and both the gears are one. rotate in the same direction. In this, usually we call the big wheel as Annular and Ring and the smaller wheel is called Pinion.

Note: – Whenever we mount more than one gears on the same shaft and the speed of all those gears is also same, in this case we call that system Compound gears.