Introduction

In the transmission system of a motor vehicle, the propeller shaft plays a crucial role in transmitting torque between the gearbox and the differential. At the connection points, universal joints are employed to allow the transmission of torque at angles. This post will explore the parts, types, and uses of universal joints in the context of a motor vehicle’s transmission system.

U- Joint

A universal joint, or U-joint, is utilized when two shafts need to be connected at an angle to transmit torque. In the transmission system, U-joints are employed to connect the transmission main shaft, propeller shaft, and differential pinion shaft. There are three main types of universal joints: Cross types, Ball and Turning Types, and Constant Velocity Types.

What are The different types of universal joints

The universal joint may be three Types

- Cross-Types universal joint | Spider And two-Yoke Types

- Ball and turning Types

- Constant Velocity Type

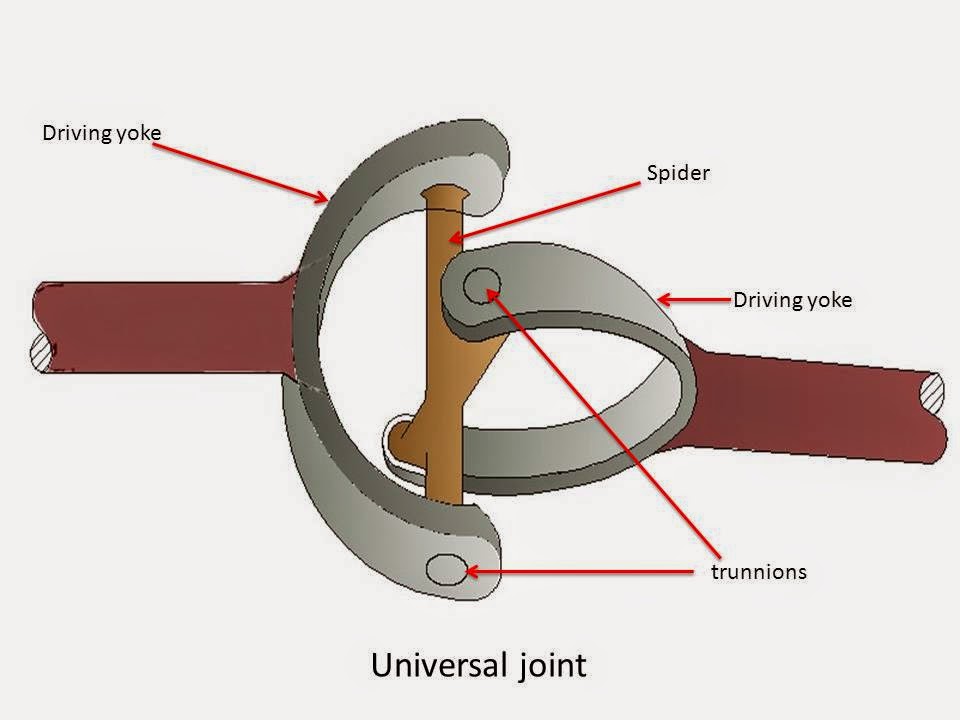

1) Cross-Types universal joint

A basic universal joint consists of two Y-shaped yokes—one on the driving shaft and the other on the driven shaft—and a crosspiece known as the spider. The spider has four arms, forming a cross. The bearings are held in place by rings dropped into undercuts in the yoke bearing holes. In applications like connecting the propeller shaft to the rear axle gear shaft, the slip joint may be omitted for a direct connection between the two units.

It is known as a cross-type of spider, the bearing is held in place by ring heat drop into an undercut in the yoke bearing holes.

one Yoke is integral with the hub that holds the female end or the slip joint when the joint is used between the propeller shaft and rear axle gear shaft the slip joint is omitted so that a direct connection is made between the two unite

2) Ball and turning Types U-Joint

The Ball and trunnion-type universal Joint comprises a ball head attached to the end of the propeller shaft, with a pin pressed through it. Two balls fit over the ends of the pin, retaining roller bearings between them within a U-shaped channel in the body. Centering bottoms and button springs assist in keeping the pin centered. This type allows for compensating varying angles of drive and acts as a slip joint.

The Companion Flange is splined to the other Shaft the rotary motion is carried out through the pin and balls The balls can move back and Forth in the Channels of the body to compensate for varying angles of drive at the same time, they act as a slip joints by slipping into or out of the channels.

3) Constant Velocity Type U- Joint

The Constant Velocity Universal Joint consists of two individual U-joints linked by a ball and socket. This configuration permits uniform motion as the two joints operate at the same angle. Acceleration from one joint is canceled out by the deceleration from the other, resulting in smooth and constant motion.

Tags