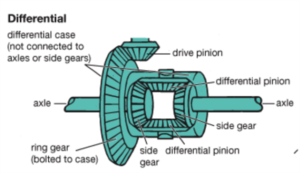

Differential is a part of the inner axle assembly which includes the differential rear axles, wheels and bearing the differential consists of a system of gear arranged in such a way that connects the propeller shaft with the rear axles the torque transmitted to each wheel is always equal the purpose of the differential is to provide the relative movement to the two rear wheels when the car is taking a turn.

HOW IT WORKS ?

At the time of straight road.

During the vehicle runs straight, the wheels of the rear axle will be screened by the drive pinion through the ring gear differential case, wheel-wheel differential gear pinion shaft, wheel-pinion differential gears, side gear teeth is not spinning, remain to be drawn into the ring gear rotation. Thus the spin on the wheel left and right alike.

At the time of turning.

At the time of vehicle turning left prisoners left wheel is bigger than the right wheel. If the differential case with the ring gear rotates the pinion will rotate on its axis and also the movement around the left side gear, so round the right hand side gear increases, the side where the number of revolutions of the gear which is 2 times round the ring gear. It can be said that the average second round gear is comparable with the rotary ring gear. as it should.

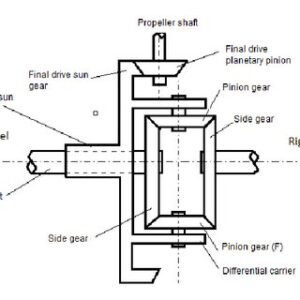

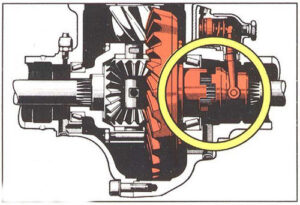

Construction

The construction of a simple differential . airing gear (crown gear ) is attached to the case ,the case is rotated both the sun gears rotate and thus both wheel turn which are attached to the outer end of the rear axles then when the differential cage is rotated, the planet gears will also rotate as they run around as the axle sun gear when the car is taking a turn

WORKING PRINCIPLE OF DIFFERENTIAL

The basic principle of the differential gear unit can be understood by using equipment that consists of two gears pinion and rack. Both rack can be moved in the vertical direction as far as the weight rack and slip resistance will be lifted simultaneously. Placed between the tooth pinion rack and pinion gear connected to the braces and can be moved b y these braces. When the same load “W” placed on each rack then braces (Shackle) is pulled up the second rack would be lifted at the same distance, this will prevent the pinion gear does not rotate. But if a greater burden placed on the left rack and pinion buffer will then be drawn up along the gear rack rotates the load gets heavier, which is attributed to differences in prisoners who are given the pinion gear, so the smaller the burden will be lifted. The raised rack spacing is proportional to the number of turns pinion gear. In other words that rack gets custody larger still and while prisoners who received a smaller load will move. This principle is used in the planning of differential gears

y these braces. When the same load “W” placed on each rack then braces (Shackle) is pulled up the second rack would be lifted at the same distance, this will prevent the pinion gear does not rotate. But if a greater burden placed on the left rack and pinion buffer will then be drawn up along the gear rack rotates the load gets heavier, which is attributed to differences in prisoners who are given the pinion gear, so the smaller the burden will be lifted. The raised rack spacing is proportional to the number of turns pinion gear. In other words that rack gets custody larger still and while prisoners who received a smaller load will move. This principle is used in the planning of differential gears

Differential Diagram

FUNCTIONS OF DIFFERENTIAL

1. Further reduces the rotations coming from the gear box before the same are passed on to the rear axles.

2. Changes the direction of axis of rotation of the power by 90o i.e. from being longitudinal to transverse direction.

3. To distribute power equally to both the rear driving axles when the tractor is moving in straight ahead direction.

4. To distribute the power as per requirement to the driving axles during turning i.e. more rotations are required by the outer wheel as compared to the inner wheel – during turns.

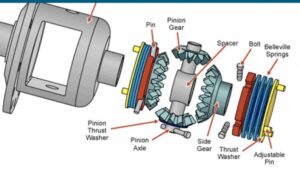

THE MAIN COMPONENTS OF THE DIFFERENTIAL

1. Bevel Pinion Gear

2. Crown wheel gear

3. Differential cage

4. Differential star Gear or Planet Pinion Gear

5. Differential axle (sun) gear

- Pinion Gear or Final redaction:- the final drive consists of a bevel pinion and crown wheel the bevel pinion is mounted on a shaft which is connected to the propeller shaft . oil meshes with the crown wheel of the differential unit the final drive provides a fixed gear reduction to turn the drive at 90 degree and to give required speed

- Crown wheel gear:- The crown wheel is attached to the power bevel pinion. The crown wheel is attached to the differential case that accesses the power planet gear via the differential case.

- Differential cage;- Differential cage is a solid structure that is attached to the crown wheel. When the crown wheel is rotated, the planet pinion gear also rotates with the help of the case and the power reaches the listening gear.

- Differential star Gear or Planet Pinion Gear :- The job of the planetary-gear is to reach equal power to both the sun gears. In a planetary- gear system the gears that mesh with and resolve about the sun gear they also mesh with the ring ( or internal) Gear.

- Differential axle (sun) gear:- The function of the sun gear is to reach the power from the differential to the wheel. Sun Gear gets its power from the planet pinion . the rear axle is not a single piece but it is in two halves connected by the differential one part is know as half shaft. inner end of the half shaft is connected to the sun gear of the differential and the outer end of the drive wheels

Types of Differential

The following are the types of differential:

- Open differential

- Limited-slip differential

- Locking differential

- Torque-vectoring differential

- Torsen differential

- Welded differential

Open Differential

These types of differentials are the most essential and only allow individual wheel speed or slip to be changed. In good road conditions, this allows the outer wheel to spin at a faster speed than the inner wheel. This allows for different wheel speeds on one axle, thus reducing tire wear compared to a locked differential. It also allows the wheel to send torque with more traction.

Locking differential

These types of differential use a clutch and springs to actuate the lock which sends the same amount of power to each wheel, no matter the traction condition. It essentially forms a solid axle.

The advantage is the locking differential ability to achieve a greater amount of traction because the full amount of torque is always available to one wheel and is not limited by the lower traction of a single wheel

Limited-slip differential

A limited-slip differential works similarly to an open differential. They transfer torque to each wheel independently under good road conditions.

An open differential can cause the tire to slip under hard cornering or heavy acceleration. But a limited-slip differential prevents the amount of torque from passing into the sliding tire (the one with the least resistance).

Torque-vectoring differential

This type of differential uses a set of sensors and electronics to receive data from various matters (road surface, throttle position, steering system, etc.) to activate an electronically actuated clutch and a controller. It is known as an active differential.

They operate in the most efficient manner resulting in a truly dynamic, high-performance driving experience. A torque-vectoring difference is found in high-performance rear-wheel drive and all-wheel drive vehicles.

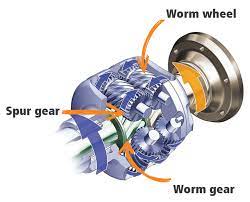

Torsen differential

The Torsen means torque-sensing. These are types of limited-slip differential that use some accelerated gearing to produce an impact without using a clutch or fluid resistance.

This can be achieved by adding a collection of worm gears to a conventional gear setup of the open differential. These worm gears working on each axle provide the necessary resistance to enable torque transfer.

Welded differential

This is a type of locked differential and is known as a spool differential. It is welded permanently to a fixed axis by an open gap. This is usually done in specific situations where the features of locked differential make it easier for both wheels to spin simultaneously.

This is generally not recommended because the heat from welding can hazard the component’s strength and increase the risk of part failure